Cutting

Three different Cutting Systems

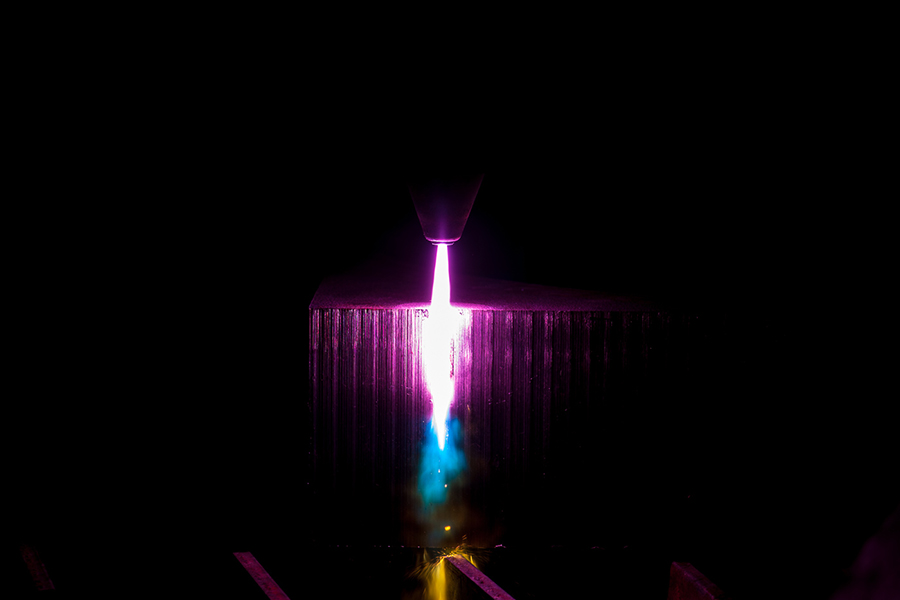

Plasma Cutting

Plasma Cutting

Underwater, high-focus and fine-focus plasma cutting: suitable for fast and inexpensive serial and single part production.

Advantages:

- High cutting speed

- All stainless steel grades of 3 mm – 150 mm sheet thickness

- High-Focus and Fine-Focus for narrow tolerances

- Under-water cutting for warp-free profiling

Waterjet Cutting

Waterjet Cutting

Precise cutting with narrow tolerances and finest contours.

Advantages:

- Delay-free, precise and fine profiling

- No reaction to heat, hardness increase, bending or tension

- Tight tolerances depending on the thickness of the shee

- Close to right-angled cutting edge

- Parts are instantly ready for installation

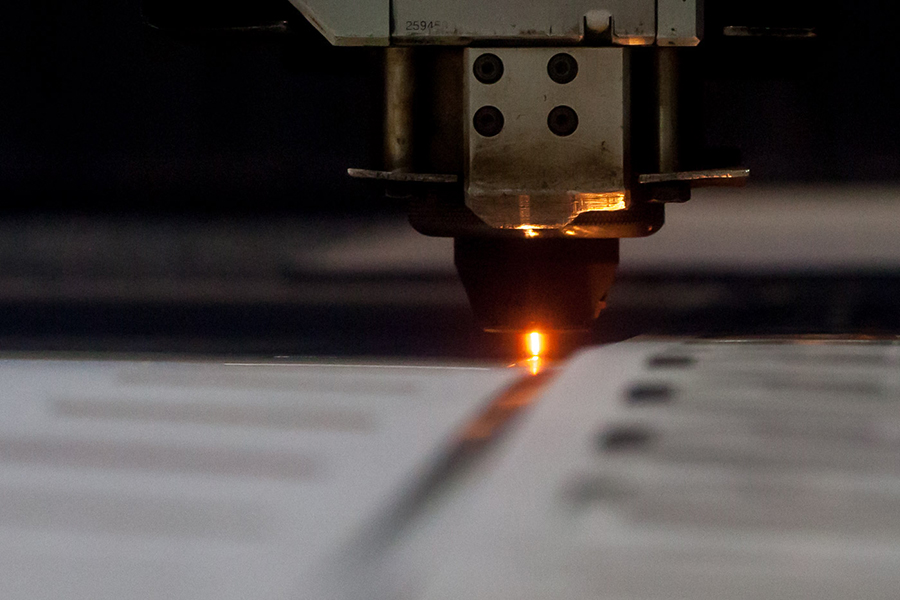

Laser Cutting

Laser Cutting

TRUMPF laser system. Ideal for serial and individual production with „thinner“ material.

Advantages:

- Very high cutting speed

- All thicknesses up to 20 mm

- Narrow tolerances depending on the thickness of the sheet

- Excellent cutting quality with a almost right-angled cutting edge

- Precise, warp-free cut-to-size profiling

Wartenburgerstrasse 1C/TopC2

A-4840 Vöcklabruck

UID: ATU 662 282 45

Am Stahlwerk 17

45527 Hattingen

UID: DE 296 014 812

Otto-Lilienthal-Str. 1

28199 Bremen

96 Avenue du Progrès

„Chassieu Park“

69680 Chassieu / Frankreich

Copyright © 2017 EST Edelstahl-Schneidtechnik GmbH, Am Stahlwerk 17, 45527 Hattingen, UID: DE 296 014 812. All Rights Reserved